- tecnotales.com

- September 20, 2024

- 0 Comments

Robot Palletizer: The Future of Efficient Material Handling

In today’s fast-paced industrial world, businesses are constantly searching for ways to increase productivity, reduce costs, and improve workplace safety. One revolutionary solution is the robot palletizer. From warehouses to factories, these advanced machines are transforming how products are handled, stacked, and transported.

At TecnoTales, we provide only information to help industries understand new technologies. In this article, we’ll explore robot palletizers, their types, benefits, comparisons with manual palletizing, and how they are shaping industries in regions like Phoenix, San Jose, and the Bay Area.

What is a Robot Palletizer?

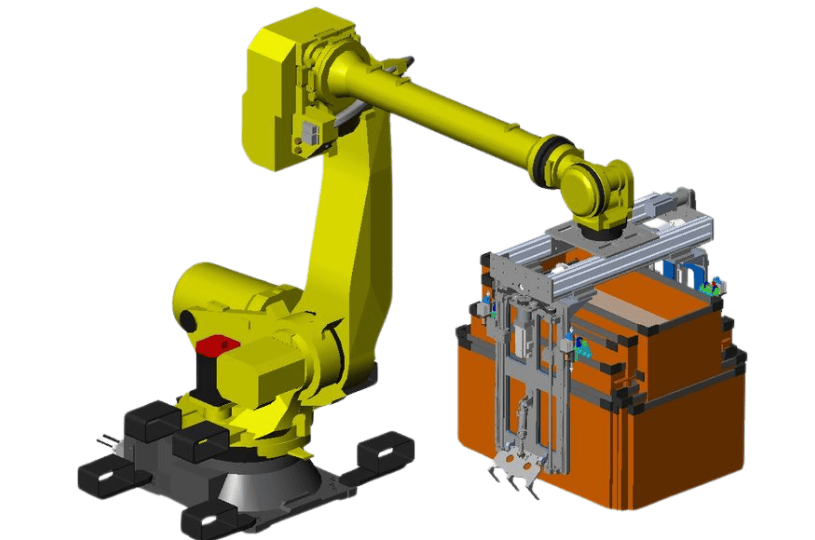

A robot palletizer is a machine designed to automatically load, stack, or organize goods onto pallets for storage or shipping. Unlike manual palletizing, which relies heavily on human labor, robotic palletizers bring speed, accuracy, and consistency to material handling.

These machines are used across industries such as food, beverages, pharmaceuticals, logistics, and manufacturing. From robotic bag palletizers to robot pallet movers and robotic pallet jacks, businesses can choose different types depending on their needs.

How Do Palletizing Robots Work?

A palletizing robot operates using a combination of robotic arms, sensors, conveyors, and software. Here’s a simplified process:

Products move on a conveyor belt.

The robot identifies the product using vision or sensors.

It picks up the product with a gripper or suction system.

The item is then stacked on a pallet in a programmed pattern.

Once the pallet is full, a robotic pallet wrapper or pallet wrapping robot secures the load.

This automation reduces manual lifting, enhances safety, and boosts efficiency.

Conventional vs Robotic Palletizing

Conventional Palletizing

Conventional palletizing uses mechanical equipment and requires significant manual labor. It is often slower, less flexible, and can result in inconsistencies.

Robotic Palletizing

In contrast, robotic palletizers adapt quickly to different product sizes, patterns, and stacking requirements. Whether you need storeroom robotic palletizers racking in San Jose or stacking frames in Phoenix, robotics bring versatility and reduced errors.

Robotic vs Conventional Palletizers

The main difference lies in efficiency, adaptability, and cost savings. While conventional systems are cheaper upfront, robotic palletizers provide long-term returns by reducing labor costs and minimizing workplace injuries.

Manual vs Robotic Palletizing

Manual Palletizing

Manual palletizing involves workers physically stacking goods on pallets. It is labor-intensive, time-consuming, and poses risks of back injuries and fatigue.

Robotic Palletizing

When comparing manual vs robot palletizing, the differences are clear robots are faster, safer, and more accurate.

Types of Robot Palletizers

There are several types of palletizing robots, each designed for specific needs:

Robotic Bag Palletizer:

Specially designed to handle bags of products like grains, flour, or cement.

Robotic Pallet Mover & Robot Pallet Jack:

These machines transport loaded pallets across the warehouse, replacing manual pallet jacks.

Robotic Pallet Wrapper:

Also known as a pallet wrapping robot, it secures stacked goods for safe transport.

Robot Pallet vs Pallet Robots:

While both terms are used interchangeably, they refer to automated machines that streamline stacking and handling processes.

Storeroom Robotic Palletizers in Key Regions

Phoenix

Businesses in Phoenix benefit from storeroom robotic palletizers stacking frames and racking systems that optimize warehouse storage.

San Jose

San Jose companies are increasingly adopting storeroom robotic palletizers shelving, racks, and stacking frames to enhance supply chain efficiency.

Bay Area

The storeroom robotic palletizers in the Bay Area are known for integrating advanced robotics with smart storage systems to meet growing logistics demands.

Benefits of Using Robot Palletizers

1. Increased Efficiency

Robots can operate continuously without fatigue, handling thousands of products daily.

2. Improved Workplace Safety

Replacing heavy lifting with robotic pallet jacks reduces injuries.

3. Cost Savings

Although the upfront cost is high, long-term savings on labor and errors make them profitable.

4. Flexibility & Scalability

From robotic pallet wrappers to robot pallet movers, businesses can scale operations easily.

5. Better Quality Control

Consistent stacking patterns minimize product damage.

Future of Palletizing: Autonomous Robots

The future belongs to autonomous pallet robots that integrate artificial intelligence and IoT technology. These machines will self-navigate warehouses, handle inventory, and even work with other robotic systems for a fully automated supply chain.

Conclusion

The robot palletizer has become a vital tool for modern industries seeking efficiency, safety, and scalability. Whether it’s storeroom robotic palletizers racking in San Jose, stacking frames in Phoenix, or autonomous pallet robots in the Bay Area, businesses are rapidly adopting robotic solutions.

As industries move towards full automation, palletizing robots will continue to evolve, integrating AI and smart technology to reshape the future of logistics and supply chain management.

At TecnoTales, we remain committed to providing valuable information on emerging technologies to help you stay informed and ahead in the competitive world of automation.

FAQs

Q1. How do palletizing robots work?

Palletizing robots work by using robotic arms, sensors, and grippers to pick up products from conveyors and stack them onto pallets in pre-programmed patterns.

Q2. What is a robot palletizer?

A robot palletizer is an automated machine that stacks, organizes, or loads products onto pallets for easier handling and transportation.

Q3. How much does a robotic palletizer cost?

The cost of a robotic palletizer varies between $80,000 to $150,000 depending on type, capacity, and features. Customized solutions may cost more.

Q4. Can palletizing robots handle different products?

Yes, robotic palletizers can handle cartons, bags, boxes, and bottles, making them versatile across industries.

Q5. What is a depalletizing robot?

A depalletizing robot is designed to unload products from pallets, the opposite of palletizing. It improves efficiency in warehouses where goods need to be unpacked quickly.